| Tags | show all posts |

Brunswick Billiards - Pool Table Manuafacturer Review

Brunswick Pool Tables

To see our range of Brunswick pool tables please click on the below link:

https://www.pooltablesonline.co.uk/search-by-manufacturer/

Brunswick Pool Tables

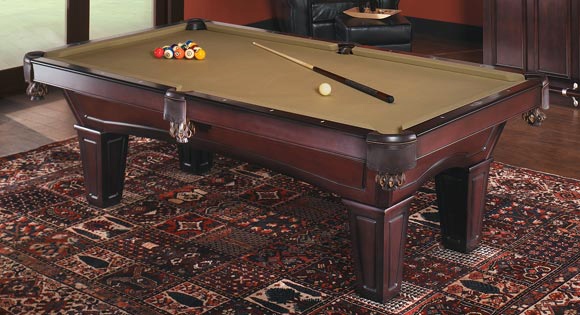

Brunswick is without a doubt one of the most famous names in pool. A superb company with a fantastic rich history.We are delighted here at pool tables online to offer a lovely selection of Brunswick pool tables.

Brunswick produces a range of world renowned American pool tables that have graced tournaments and homes all over the world.

All these tables included professional installation in the price which will be carried out by the main UK fitting team.

So what makes them so good? Below we outline just why this world famous billiard company has the fantastic reputation that it thoroughly deserves. There is only one place to start and that's at the beginning.

The Brunswick Story

A Legendary Name. A Humble Beginning.

Brunswicks Founder - J.M.Brunswick

In 1845, John Moses Brunswick, of Cincinnati, Ohio, was steadily building a solid reputation as a builder of fine carriages.

It was a good living; a solid career path for an ambitious young man in the mid-19th century.

Then, somewhat suddenly, everything changed. When Brunswick first laid eyes on a finely crafted billiard table, he knew he had found his calling.

As a gifted artisan with a passion for woodworking, the young man was captivated by the table’s intricacy, detail, fine workmanship, and beauty. He saw more than a table; he saw an opportunity to build something with unlimited potential and lasting beauty.

"If it is wood, we can build it — and we can build it better than anyone else," he declared.

True to his word, he completed his first billiard table soon after. By 1850, The tables were fast becoming known around the world as masterpieces of original craftsmanship and design. Within 10 years, he had built an impeccable reputation for fine quality, playability, and beauty and had laid the foundation of what would become the largest billiard company in the world.

The Legend Lives On.

The world has changed tremendously since then, but the companes commitment to exceptional quality remains. John Moses Brunswick’s creative vision continues to thrive at the Billiards headquaters in Bristol, Wisconsin, where we’ve been connecting generations through superior craftsmanship and innovation since 1845.

To find out more about this fabulous rich history - CLICK HERE

A Selection of the most popular pool tables

Brunswick Gold Crown Pool Table

Brunswick Allenton Pool Table

Blackwolf Pool Table

Glenwood Pool Table

Metro Pool Table

Treviso Pool Table

Mission Pool Table

Why Brunswick?

Brunswick has been the market leader for pool tables and games room furniture for many years. They offer a huge selection of quality hand crafted pool tables. These are all backed by a lifetime warranty and installed by the most skilled table fitters in the UK.

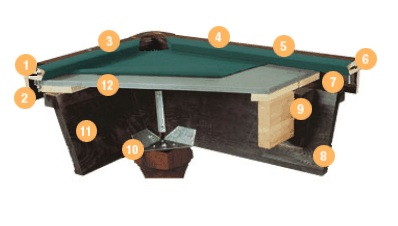

Below we outline 12 differences that make a Brunswick table not only great value but also better to play on.

Brunswick 12 point table advantage

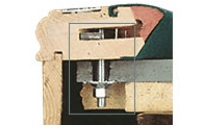

1. Brunswick uses a high performance nut plate. This is exclusive to the company and is used to attach the cushion rails to the slate. This allows the fitter to apply around 70% more torque to each connection. This is far greater than can be applied to the standard T-Nut cushion fixing. This results in a solid, seamless, transition between the rail and slate and provides enhanced performance and playability.

Brunswick Pool Tables

2. A hardened domed washer is used on Brunswick tables. What this does is grip the slate and the cushion rail together. As it directly locks the rail and slate it prevents the washer from turning over time or sinking into the wood itself. This means the cushion and rail and slate joint provides a constant connection that will prevent loosening and outlast its competitors.

BRunswick Pool Tables

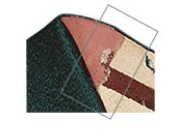

3.Superspeed Cushion Rubber - Brunswick have used the high quality cushion rubber on their table range for over 70 years. They are produced exactly to the companies specification and is not an off the shelf standard range of rubber. The results of this top of the range cushion rubber is an exceptionally consistent rails on every produced table.

Superspeed cushion rubber incorporates a thin layer of cotton canvas vulcanised into the top and back surfaces of the cushion. This feature results in controlled ball penetration and greater rebounding accuracy.

Brunswick Pool Tables

4.High pressure bonding - The name of the game is precision and when Brunswick bonds the cushion rubber to the cushion rails this is exactly what happens. This is a very important element to the performance and play of a table. Brunswick use automated pneumatically controlled machines to bond the rubber. This provides a precision fit that achieves superior accuracy and consistency in their tables.

Brunswick Pool Tables

5.Accurate Nose height - The nose height of the cusion rubber is the crucial element in getting the perfect bounce and rebound. As the rubber is put onto the rail with automated pneumatically controlled machines you are guaranteed a perfectly correct rubber nose height. This consistent rubber factor means the rails meet the standard 64% of a 2 1/4 inch diameter pool ball.

Brunswick Pool Tables

6. Solid Hardwood Rails - Brunswick cushion rails are very high quality. Produced from solid Hardwood these machined rails are made to an exacting standard and provide a solid foundation behind the cushion rubber which ensures a superb performance.

Brunswick Pool Tables

7. Machined recessed area - Brunswick cushion rails have a machined recessed area. This means that when the cloth is stapled to the rail the fitters can use as many staples as they like to provide a tight cloth fit. This is in the knowledge that the staples will never interfere in any way with the rail attachment to the slate.

Brunswick Pool Tables

8. Stable Joinery Construction - Brunswick for many years has used the finest joinery techniques when constructing pool tables. These trusted methods include panels being glued with alternating grain patterns. This creates a much stronger and stable furniture construction that will last for generations.

Brunswick Pool Tables

9. Solid wood dovetail supports - The table frame is supported with thick solid wood cross supports that utilise dovetail joinery. This massively enhances the slate support and becomes an integral part of the frame. This means the slate is supported as if it was a one piece slate and achieves superior table performance.

Brunswick Pool Tables

10. Rock Solid Ready To Install - Brunswick tables are ready to assembly by our experienced fitters. They tables are built using machine nut and bolt construction and galvanised steel leg plates. This achieves a rock solid fine furniture product that is easier to deliver and install in your home.

Brunswick Pool Tables

11. Kiln-dried, Stained, and Sealed - Brunswick aim is to provide customers with an exceptional product that will last a lifetime. All the solid wood materials used in production are kiln-dried to a 6-8% moisture level. They wood is then stained and sealed to keep moisture out. A multi-step harwearing fine furniture finish completes the look. This is the sort of thing that separates these tables from it's competitors.

Brunswick Pool Tables

12. Certified Slate - A Brunswick slate is not just any old standard table slate. They all must pass a rigid quality requirement before it receives a Brunswick certified sticker. The slates themselves are diamond-honed, precision-machined and levelled to within ten-thousandths of an inch. These slates are cured for an extended period of time to assure a superb stability. They are checked for flatness on the top and the bottom at least four times through the machining and curing process. This is to a standard twice exceeding BCA specifications. Every single slate is thoroughly quality checked, inspected and certified to ensure the ultimate playing surface. (see below video)

Brunswick Pool Tables